5 Key Factors to Consider for Warehouse Cleanouts

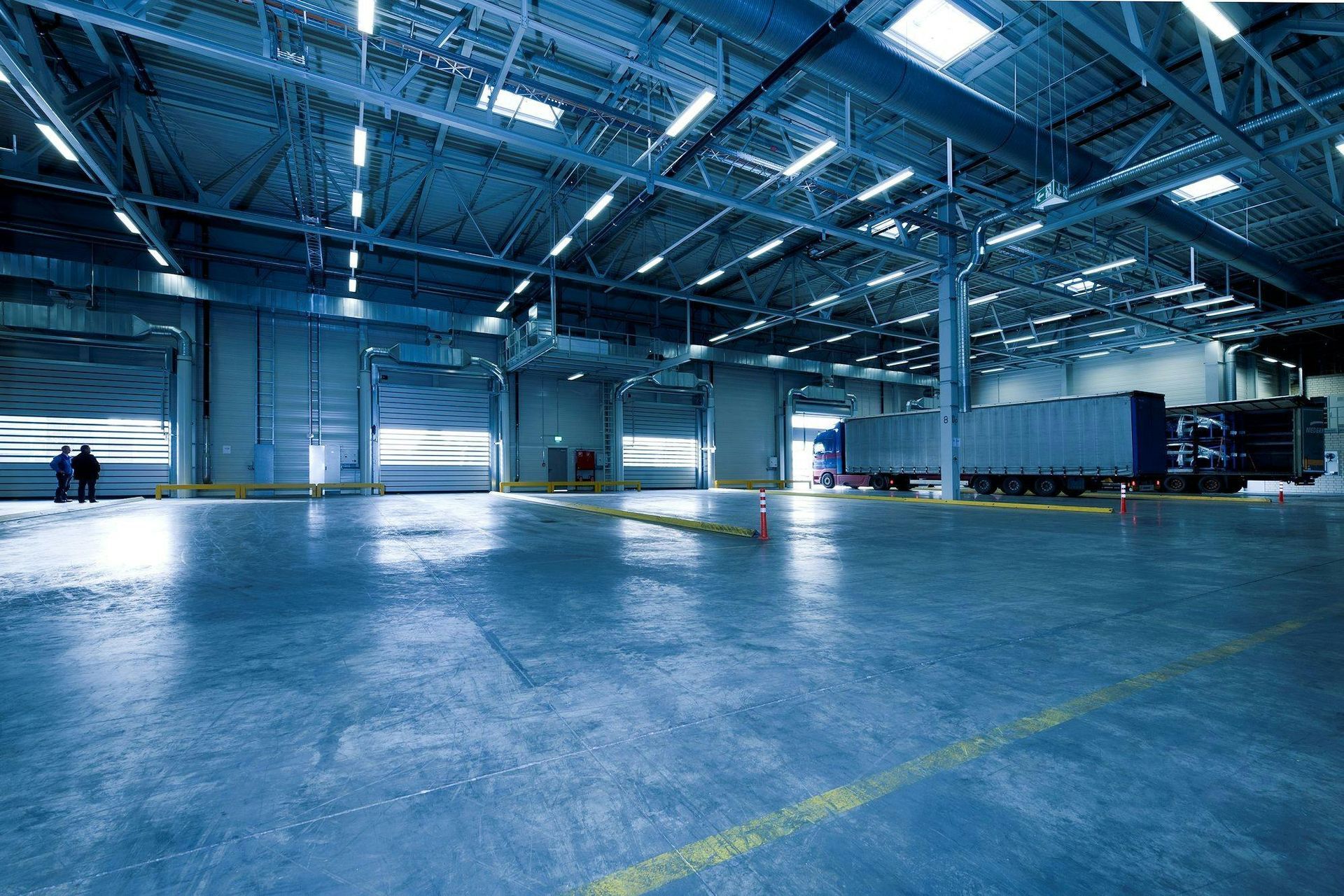

When the time comes to clear out a warehouse, it's not just about throwing things away—it's a comprehensive process that requires careful consideration and strategic planning. Warehouse cleanouts are a significant task, especially when the space is filled with years of accumulated inventory, office equipment, or industrial debris. Whether you're preparing for a move, reorganization, or simply optimizing the space, there are several key factors to keep in mind to ensure a smooth and effective cleanout. In this article, we’ll cover five essential factors that will help you navigate the warehouse cleanout process.

Essential Steps for Efficient Warehouse Cleanouts

When preparing for a warehouse cleanout, organization is key. Start by categorizing items into groups such as what needs to be kept, sold, recycled, or disposed of. This ensures a smoother process, helping you decide what to do with each item. It is also essential to evaluate your space and plan how to optimize it for future use, potentially rearranging or adding new storage solutions. A well-thought-out sorting system saves you time and helps maintain a clutter-free space.

In addition to organizing, waste disposal and recycling should be prioritized. Make sure to dispose of hazardous materials correctly, as improper disposal can lead to significant issues. Consider hiring a junk removal service to handle bulk waste efficiently, ensuring all items are dealt with according to local regulations. By planning the cleanout and waste removal process ahead of time, you’ll avoid disruptions in your operations and maintain a clean and safe environment for the team.

Key Considerations for Successful Warehouse Cleanouts

Warehouse cleanouts can be daunting, but having a strategy is essential to ensure an efficient process. Start by organizing the warehouse into categories to help determine what should be kept, sold, or disposed of. Planning for waste disposal, recycling, and repurposing items ensures that nothing is left behind without a clear decision. By handling the cleanout in stages and sticking to a clear plan, the process becomes more manageable and effective for future use.

Another critical factor to consider is safety throughout the cleanout. As heavy items and industrial materials are often involved, appropriate safety measures like protective equipment should always be used. In some cases, hiring professional junk removal services will ensure that the cleanout is done quickly and safely. Taking these precautions not only improves the overall efficiency of the cleanout process but also guarantees that your warehouse remains secure and organized.

Organizing and Categorizing Items: The First Step to Efficiency

The initial phase of any warehouse cleanout should always be about sorting and categorizing the items inside. A warehouse can accumulate a vast array of things over time—from old equipment to obsolete inventory. The first step is to go through everything and determine what stays, what goes, and what can be recycled or repurposed.

Start by creating categories:

Items to Keep: These are things you still use or plan to use in the near future. Mark them clearly and store them in an area that will be easy to access once the cleanout is completed.

Items to Sell: If you have equipment, materials, or inventory that are still usable but no longer serve your business needs, consider selling them. Depending on the items, you could have a yard sale, list them online, or approach resellers.

Items to Donate or Recycle: Many items might be too worn out or outdated to sell but can still be donated to charity or recycled in a way that benefits the environment.

Items to Dispose Of: Include anything broken beyond repair, hazardous materials, or items that no longer serve a purpose. Proper disposal ensures safety, compliance with regulations, and helps maintain an organized, clutter-free workspace.

By categorizing early on, you can streamline the entire cleanout process and prevent unnecessary clutter from re-entering your warehouse.

Planning for Waste Disposal and Recycling

Once you’ve sorted through the items and identified what needs to be discarded, you’ll need to plan for how to dispose of them properly. This is an often-overlooked aspect of warehouse cleanouts, but it is crucial for both safety and compliance reasons. Without proper waste disposal, your cleanout could turn into a bigger problem than anticipated.

Hazardous Materials: If your warehouse has accumulated any hazardous materials, it is important to consult with professional waste disposal services. These materials could include chemicals, solvents, and old batteries. Improper disposal can lead to hefty fines or environmental damage.

Electronic Waste: Electronic items such as old computers, printers, or machinery should be handled properly through certified e-waste recycling programs. Many of these devices contain materials that can be harmful to the environment if not disposed of properly.

Bulk Waste: For large-scale disposal, you may want to hire a junk removal service or rent dumpsters to handle the sheer volume of items. Be mindful that some junk removal services provide recycling as part of their offering, allowing you to dispose of your waste in an environmentally responsible way.

Proper waste management during a warehouse cleanout doesn’t only keep the environment clean, but it also ensures your business stays compliant with local and federal waste disposal laws.

Assessing the Layout and Space Utilization of the Warehouse

Another key consideration during a warehouse cleanout is how the space will be used post-cleanout. As you begin to declutter, take a moment to reassess the layout of the warehouse. If you’re clearing out old inventory or obsolete items, this could be an excellent opportunity to reorganize the space in a more efficient manner.

Ask yourself the following questions:

How much space do you need? After eliminating unwanted items, do you need the space for inventory storage, equipment, or expansion? This is the time to plan for future needs.

How can you maximize storage? If your goal is to create more room, look for ways to maximize vertical storage with shelving or racks. Consider creating designated zones for specific tasks—such as a shipping area, packing area, and inventory storage area—to streamline operations.

Is the layout still functional? As businesses grow and evolve, their needs change. What worked a few years ago may no longer be the most efficient. Consider using warehouse management systems (WMS) or design software to optimize the layout for maximum workflow and organization.

Space optimization can be a game-changer in warehouse operations. By taking the time to consider your layout during the cleanout, you can ensure your warehouse is well-organized and functional for years to come.

The Importance of Safety and Security Measures

Safety should always be a priority during any warehouse cleanout. When dealing with heavy items, industrial equipment, or hazardous materials, it is essential to take the necessary precautions to prevent accidents. A clean warehouse is not only more efficient, but it is also safer for the employees who will be working there.

Personal Protective Equipment (PPE): Depending on the nature of the cleanout, employees or contractors involved in the cleanout should wear appropriate PPE, such as gloves, safety goggles, steel-toe boots, and dust masks.

Training and Supervision: If the cleanout involves moving large or heavy items, make sure all workers are properly trained in lifting techniques and handling equipment safely. Supervisors should be on hand to monitor the process and ensure safety protocols are being followed.

Handling Heavy Equipment: For larger equipment or machinery, it is often best to hire professionals who are trained in dismantling and moving industrial equipment. They will have the tools and experience necessary to remove items safely and efficiently.

By ensuring proper safety measures are in place, you can prevent injuries and create a safer environment for all workers involved in the cleanout.

Timeframe and Budget Considerations

Lastly, one of the most critical aspects of any warehouse cleanout is time and budget management. While it may be tempting to dive in headfirst and start clearing things out, a cleanout project needs to be carefully planned in order to avoid unnecessary delays and costs.

Start by defining a clear timeframe for the cleanout. How much time do you have to complete the process? Will the cleanout affect ongoing operations, such as inventory or shipping? Having a realistic timeline is essential to ensure your cleanout doesn’t interfere with business activities or lead to unexpected downtime.

Budgeting for the cleanout is also an important consideration. You may need to factor in the cost of:

Hiring professional junk removal services or labor: If the project is too large for your internal team to handle, outsourcing the cleanout can save you time and effort, but it is important to get quotes and set expectations beforehand.

Waste disposal fees: Depending on the volume of waste, you may need to rent dumpsters or pay for bulk waste removal. Be sure to include these costs in your budget.

Equipment rentals: If you need specialized tools or machinery to help with the cleanout, such as forklifts or pallet jacks, factor in the rental costs.

By planning ahead, you can avoid unexpected costs and make the cleanout process more efficient and cost-effective.

Conclusion

Warehouse cleanouts are a necessary but complex process, and a lot goes into ensuring it is done correctly. From organizing and categorizing items to managing waste disposal and optimizing the layout, each step requires careful planning and attention to detail. Safety and security should always be prioritized, and a clear timeframe and budget will help keep the project on track. With these five key factors in mind, you can tackle any warehouse cleanout with confidence and efficiency.

For a professional cleanout service in Forney, Texas, contact Kick It Junk Removal & Hauling. They specialize in warehouse cleanouts, offering reliable, fast, and eco-friendly solutions.